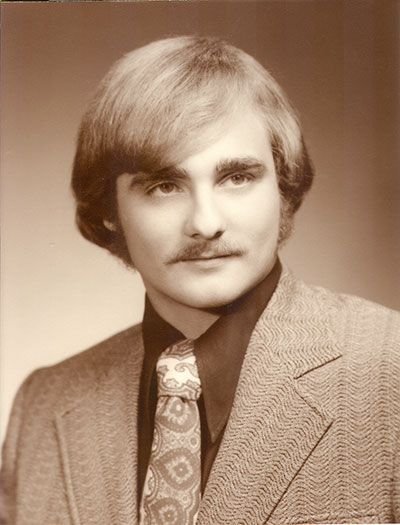

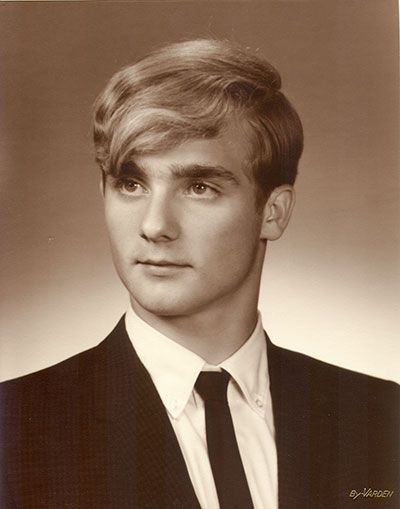

About The Author

Kenneth William Kayser through the early years....

Ken's Mom, Audrey Louise Nachbar and Dad, Ralph William Kayser Jr. were married in Buffalo, New York on November 25, 1949 exactly the same day GM's one-millionth Cadillac was built. Ken was born on Thanksgiving Day November 23, 1950 when Oldsmobile was ready to engineer GM's first automobile with experimental fuel injection. Oldsmobile completed GM's first fuel injected automobile a year later about Ken's first-birthday.

Twenty-three days before Ken's second birthday Chevrolet finished building the first experimental Project Opel Sports Car EX-52 and it was test driven by Maurice Olley who released it to Harley J. Earl for GM Styling's transformation into the 1953 GM Motorama Corvette. Harley Earl purchased the first 1953 Production Corvette E53F 001003 just after Ken's third birthday in December 1953.

On Ken's fourth birthday, November 23, 1954 Chevrolet assembled GM's Fifty-Millionth vehicle; a Golden Anniversary 1955 Chevrolet Bel Air with GM President Harlow H. Curtice leading a parade down Saginaw Street in Flint, Michigan.

When Ken turned five years, Zora Arkus-Duntov was testing his Corvette Camshaft in Corvette Test Car #5951 at the GM Arizona Proving Ground at 155 MPH in preparation for his sucessful 150 MPH Flying Mile at Daytona Beach, Florida.

Zora and his engineer Ken Hansen dynamometer tested Harlow Curtice's #1 Fuel Injection Unit on September 22, 1956 and Harlow presented it to Harley Earl. On November 23, 1956 Ken's sixth birthday, Chevrolet Work Order 95017 authorized Zora to install Curtice's #1 Fuel Injection unit in Earl's GM Styling Show Car; the 1957 Super Sport Corvette. Also on November 23, 1956 Chevrolet's Work Order 17696-14 authorized Zora to perform a Special Test on his Corvette "SR" Fuel Injection Duntov Cam 283 HP V-8.

At Ken's lucky seventh birthday in 1957 GM Styling was putting the final touches on its "Airfoil" full size clay model that set the body style theme for the 1963 Corvette Sting Ray.

In 1958 when Ken was turning eight, GM President Harlow Curtice retired on November 1st and was suceeded by John Gordon with Frederick Donner becoming GM's Chairman; unfortunately both anti-corporate racing zealots.

Zora had just begun engineering the "R-Car" at Ken's ninth birthday; eventually becoming the Chevrolet Engineering Research Vehicle (CERV) that Zora first tested one week after Ken's tenth-birthday at Pikes Peak.

The 1963 Corvette Sting Ray debuted at the Detroit Auto Show on October 22, 1962 one-month before Ken's twelveth-birthday.

On Ken's November 23, 1964 fourteenth birthday Chevrolet engineering officially approved the 1967 Corvette based on the 1965 Mako-Shark body. As Ken turned fifteen and sixteen Zora was conjuring up the Corvette L-88 engine and his 1965 Corvette L-88 Test Car #58053.

The 1967 Corvette was delayed one model year year and was introduced as the 1968 Corvette when Ken was accepted to General Motors Institute November 20, 1967 just three days before his seventeenth birthday when Ken began applying for G.M.I. sponsorship at Chevrolet Tonawanda.

After Ken turned eighteen in November 1968 he contracted the highly contagious "Big Block-itis" and never recovered!

Ken Kayser's GM Career...

Flint V-8 Engine, Flint Engine South & Tonawanda Motor Plant

Kenneth W. Kayser received a letter from Mr. William L. Holcomb dated December 6, 1967 stating the was selected for sponsorship to General Motors Institute (G.M.I.) by the Chevrolet Motor Plant in Tonawanda, New York. John J. Hamacher’s letter dated May 17, 1968 informed Ken to report for work at the Tonawanda Motor Plant, on June 26, 1968 as a General Motors Institute (G.M.I.) Co-operative Engineering Student.

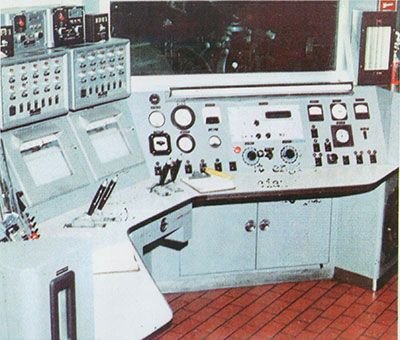

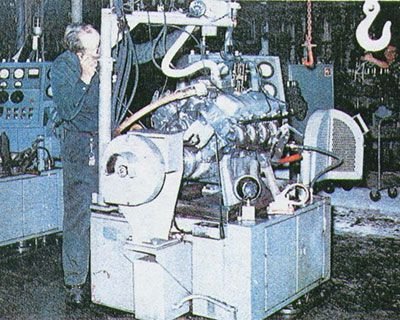

G.M.I. President Harold P. Rodes’ letter of July 22, 1968 informed Ken that his G.M.I. college career started August 19, 1968 in Flint, Michigan. During Kayser’s four six-week co-operative work terms per year at Tonawanda he spent as much time as permitted in the Mark IV engine departments; Engine Assembly Line, Mark IV Hot Test, Cylinder & Case Machining, Cylinder Head Machining, Crankshaft Machining and Connecting Rod Machining.

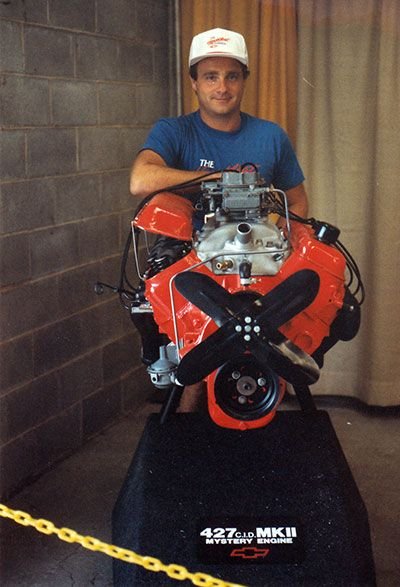

From 1987 to 1990 Kayser was the Quality and Statistical Methodology Manager for the Chevrolet - Pontiac - Canada (CPC) Tonawanda plant overseeing all four engine families including the Mark IV “Big Block”. General Motors CPC Engineering re-designed the Mark IV as the new Mark “V” engine for 1990. The redesign brought the Mark “V” up to date with new casting and machining technologies and new product features to improve; quality, reliability, durability and U.S. government mandated fuel economy and emissions regulations. The Mark “V” engine launch set new quality standards at Tonawanda, CPC and GM and it was well received by the automotive press, Chevrolet and GMC vehicle purchasers and the aftermarket marine and industrial customers. In 1991 Kayser was named Tonawanda’s Mark “V” Business Unit Manager overseeing the entire product and process from material acquisition through manufacturing to the customer base. Chip Miller, the co-owner of Carlisle Productions called Kayser and invited Tonawanda’s Mark “V” engine debut to Corvettes at Carlisle in 1991. Kayser and two very senior Mark “V” Engine Assembly line utility technicians set-up the CPC Tonawanda display in Carlisle’s T-Building.

Ken boarded the GM Air Transport Convair at the Buffalo, NY airport the next morning headed to Detroit’s City Airport to visit the US-SS top secret facility at the GM Technical Center’s Manufacturing Development Building in Warren, Michigan. After receiving the U.S. government’s security check and clearance Ken met with the US-SS Cadillac Presidential Limousine project managers and engineers to fully review the vehicle and understand the demanding acceptance and performance requirements.

Kayser then met with the Mark “V” Assistant Chief Engineer John Stier at the CPC Engineering Center to customize and adapt the bullet-proof Mark IV LS7 engine to the Cadillac limousine’s performance requirements. The Bill of Materials was complete and on the spot orders for purchased parts was issued “Rush”.

Ken elicited the support of CPC Tonawanda’s Plant Manager Donald Rust and the United Auto Workers Local #774 President Kenneth Kaiser. They developed a joint plan to make the assembly of four Cadillac limousine engines a “significant and fun Tonawanda style event”. Cadillac’s U.S. Presidential Fleet powered by Tonawanda’s new LS7 engine’s passed the US-SS test at Quantico, VA with flying colors! The US-SS presented Kayser with a U.S. Secret Service “Star” emblazoned walnut placard citing the “Outstanding People of CPC Tonawanda for their Outstanding Performance Engines in the U.S. Presidential Limousines”. With Don Rust and Ken Kaiser’s continued U.A.W. Local #774 support a fifth LS-7 display engine was built for the Tonawanda Plant Lobby with the US-SS Citation displayed on the wall behind it.

Fortunately for me Ken said he’d rather be where he could contribute the most good for GM and got right down to the business of helping resurrect the Flint V-8 Engine plants manufacturing and engineering viability through the end of 1999. Ken immediately engaged Mark Damico at CPC’s Small Block Engineering Group at Pontiac headquarters to process and expedite paperwork necessary to document Kayser’s re-engineering of the 1996 Flint V-8 engine to meet the U.S. government’s new 1996 stringent fuel economy and emissions regulations. It was no small task for an engine designed in 1952 with equipment purchased in 1953 and placed in production in July 1954 to meet the new On-board Diagnostics a.k.a. as OBD-II.

Ken asked me to approve nearly a half-million dollars to purchase his profound new design tooling to reduce the Cylinder Bore diameter tolerance from its historic 1954-1995 .003” to the 1996 .001” tolerance and the new 1996 pistons “low tension” ring package required the net cylindrical geometry specification be cut in-half to meet the emissions certification. I asked Ken one question; Can you guarantee it will work? Ken replied; No I cannot guarantee it will work, however there is no fundamental reason why it won’t work!

Kayser then took on the elimination of the forever nagging Crankshaft #5 Main Bearing “cold-start Knock” noise issue that no one could solve ever since lighter engine oils were required to reduce exhaust emissions in the mid 1980’s. Kayser adopted a known technique used since the 1960’s at race engine shops and we put it in operation at Flint V-8 too. I can tell you we met strong opposition from the bean counters at Headquarters because of the significant extra manpower required but the problem instantly disappeared too.

Ken then went after the nuisance engine vacuum warranty leaks since the mid 1980’s caused by the unused vestiges of the mechanical engine mounted fuel pump left over after changing to in-tank fuel pumps. For the upcoming 1996 OBD-II mandated “Check Engine Light” the vacuum leaks had to be eliminated to avoid utter chaos it would have caused at dealers repair shops. Kayser stopped drilling the two left over fuel pump “leak holes” and the problem disappeared too. Ken built two off-line work stations to drill the two holes only for pre 1986 service engines that required the mechanical fuel pump. The cost savings and manpower reduction more than off-set all the manpower added for the #5 Main Bearing fix.

The bottom line is that due to Kayser’s perseverance and imaginative re-engineering; the Flint V-8 engine went from GM’s 1995 worst in quality to 1996 first in quality despite its half century age handicap! Motor Trend magazine named the 1996 Chevrolet Tahoe “1996 TRUCK of THE YEAR” due to its remarkable engine in a year when there was no new truck in the industry and Motor Trend‘s judges needed a decisive factor! After displaying the Motor Trend trophy at GM Powertrain Headquarters, CPC’s V-8 Engine Chief Engineer Edward Koerner passed the prestigious Motor Trend trophy to me and I passed it to Ken who really earned it.

The Flint V-8 plant was demolished and the new Flint Engine South facility was constructed with a 2002 Model Year SORP producing the Chevrolet Trailblazer and GMC Envoy 4.2 Liter DOHC all aluminum “Vortec” L-6 engine.

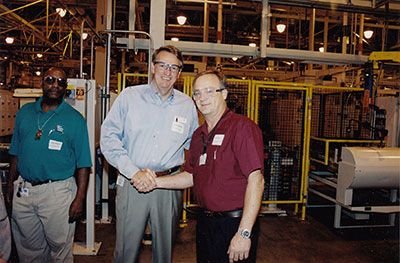

Kayser was the first person I added to my Flint South Team and became an instrumental leader. I asked him often to help others solve their technical problems and he always did. We were recognized in 2001 by GM Chairman George Richard “Rick” Wagoner Jr. with the GM Chairman’s Honors for 2000. Flint Engine South’s 4.2 L engine won Ward’s 10 Best Engines its first year and an unprecedented four consecutive years.

The 2020 C8 Corvette LT2 Engine is now in production at the Tonawanda Engine Plant.